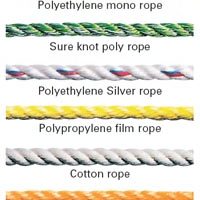

Description

| DIA | Weight | Tensile Strength | |

|---|---|---|---|

| MM | INCH | KG/200M | TON |

| 4 | 5/32 | 1.95 | 0.33 |

| 5 | 3/16 | 3.00 | 0.50 |

| 6 | 1/4 | 4.50 | 0.70 |

| 8 | 5/16 | 7.75 | 1.21 |

| 9 | 3/8 | 9.80 | 1.51 |

| 10 | 13/32 | 12.10 | 1.85 |

| 12 | 15/32 | 17.60 | 2.80 |

| 14 | 9/16 | 23.90 | 3.73 |

| 16 | 5/8 | 30.80 | 4.78 |

| 18 | 23/32 | 38.70 | 5.94 |

| 20 | 13/16 | 48.00 | 7.23 |

| 22 | 7/8 | 57.90 | 8.63 |

| 24 | 15/16 | 69.50 | 10.20 |

| 26 | 1-1/32 | 81.30 | 11.80 |

| 28 | 1-1/8 | 95.30 | 13.50 |

| 30 | 1-3/16 | 108.00 | 15.40 |

| 32 | 1-1/4 | 123.00 | 17.30 |

| 34 | 1-11/32 | 139.00 | 19.40 |

| 36 | 1-7/16 | 155.00 | 21.60 |

| 38 | 1-1/2 | 174.00 | 23.90 |

| 40 | 1-19/32 | 191.00 | 26.30 |

| 42 | 1-21/32 | 213.00 | 28.70 |

| 45 | 1-25/32 | 244.00 | 32.70 |

| 48 | 1-7/8 | 277.0 | 37.20 |

| 50 | 2 | 302.00 | 39.80 |

| 52 | 2-1/16 | 328.00 | 43.00 |

| 55 | 2-5/32 | 367.00 | 47.50 |

| 60 | 2-3/8 | 438.00 | 55.80 |

| 65 | 2-9/16 | 513.00 | 64.80 |

| 70 | 2-3/4 | 596.00 | 74.30 |

| 75 | 2-31/32 | 683.00 | 84.50 |

| 80 | 3-5/32 | 777.00 | 95.30 |

| 85 | 3-3/8 | 874.00 | 107.00 |

| 90 | 3-9/16 | 980.00 | 119.00 |

| 95 | 3-3/4 | 1,080.00 | 131.00 |

| 100 | 3-15/16 | 1,200.00 | 144.00 |

| DIA | Weight | Tensile Strength | |

|---|---|---|---|

| MM | INCH | KGS/200M | TON |

| 24 | 15/16 | 69.5 | 13.10 |

| 28 | 1-1/8 | 95.5 | 17.50 |

| 32 | 1-1/4 | 123.0 | 22.0 |

| 36 | 1-7/16 | 155.0 | 27.30 |

| 40 | 1-9/32 | 191.0 | 33.00 |

| 42 | 1-21/32 | 213.0 | 36.00 |

| 45 | 1-25/32 | 244.0 | 41.00 |

| 48 | 1-7/8 | 277.0 | 46.00 |

| 50 | 2 | 302.0 | 50.00 |

| 52 | 2-1/16 | 328.0 | 54.00 |

| 55 | 2-5/32 | 367.0 | 59.00 |

| 60 | 2-3/8 | 438.0 | 70.00 |

| 65 | 2-9/16 | 513.0 | 82.00 |

| 70 | 2-3/4 | 596.0 | 94.00 |

| 75 | 2-31/32 | 683.0 | 106.00 |

| 80 | 3-5/32 | 777.0 | 121.00 |

| 85 | 3-3/8 | 874.0 | 134.00 |

| 95 | 3-3/4 | 1,080.0 | 166.00 |

| 100 | 3-15/16 | 1,200.0 | 184.00 |

| 104 | 4-1/8 | 1,332.0 | 200.00 |

| 112 | 4-7/16 | 1,544.0 | 210.00 |

| 120 | 4-3/4 | 1,774.0 | 255.00 |

| DIA | Weight | Tensile Strength | |

|---|---|---|---|

| MM | INCH | KGS/200M | TON |

| 36 | 1-7/16 | 166 | 29.8 |

| 40 | 1-9/16 | 200 | 35 |

| 44 | 1-3/4 | 242 | 42.3 |

| 48 | 1-7/8 | 286 | 49.5 |

| 52 | 2-1/16 | 336 | 58.7 |

| 56 | 2-1/4 | 402 | 69.6 |

| 60 | 2-3/8 | 452 | 77.9 |

| 64 | 2-1/2 | 504 | 86.6 |

| 68 | 2-11/16 | 572 | 98 |

| 72 | 2-7/8 | 660 | 112 |

| 80 | 3-5/32 | 806 | 133 |

| 88 | 3-7/16 | 956 | 157 |

| 96 | 3-13/16 | 1,138 | 191 |

| 104 | 4-1/8 | 1,332 | 210 |

| 112 | 4-7/16 | 1,544 | 228 |

| 120 | 4-3/4 | 1,774 | 270 |